-

Мобильная дробилка

- вибрационный питатель щековая дробилка дубай

- каменные самоходные дробилки

- песок кварцевый кварцит

- Италия каменная дробилка оборудование для продажи

- дробильное оборудование для обработки вторсырья

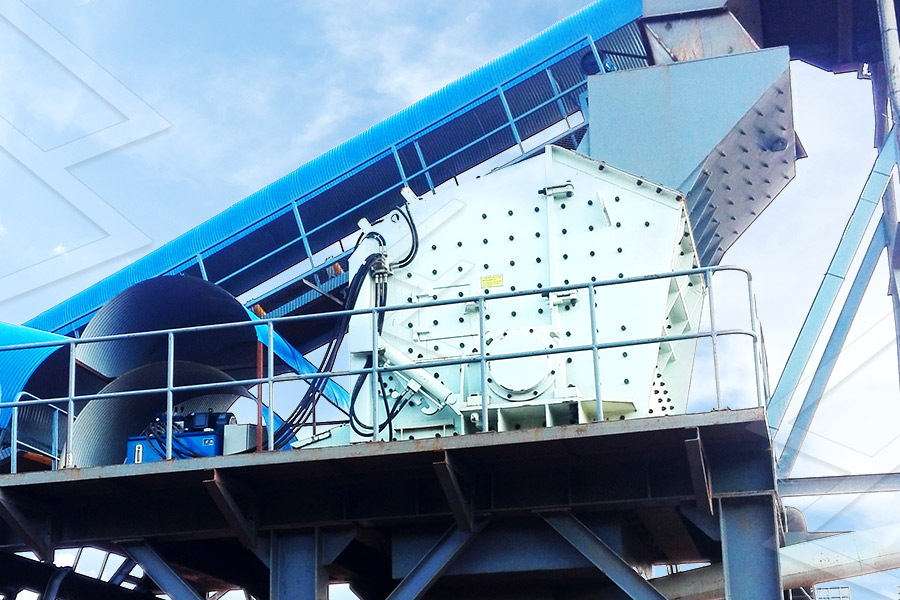

- роторная дробилка с вертикальным валом kefid

- сухого помола мельницы

- вибрационный грохот для горных пород

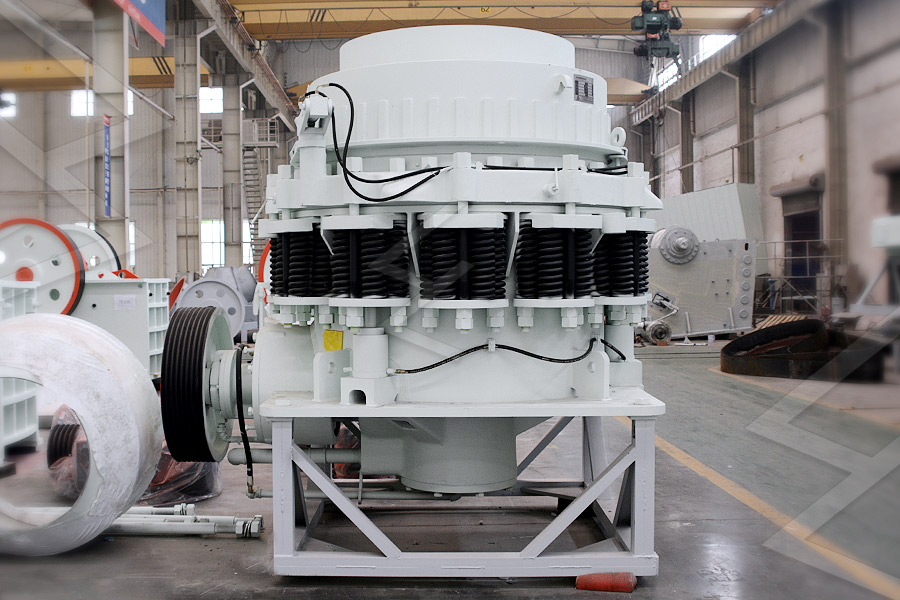

- конусная дробилка эксплуатации в Южной Африке

- используется дробилка симонс конусные продажа

<мрамор дробилка Италия

используется дробилка симонс конусные продажа

джакартская передвижная угольная дробилка Продажа дробилок и мельниц для твердых пород горное Конусная дробилка симонс цена на конусные для конусной

Read More

используется Симонс конусных дробилок продажи

используется конусных дробилок Дубай При использовании конусных дробилок uae используется дробилок для продажи в дубай конусные дробилки для продажи в

Read More

ru/используется симонс конусная дробилка для ...

Contribute to sbmboy/ru development by creating an account on GitHub.

Read More

используется VSI дробилка для продажи 36

используется VSI дробилка для продажи 36 2019-05-05T23:05:26+00:00 используется vsi дробилки для продажи 36 используется угль дробилки для продажи Россия

Read More

используется цена 3 фута конусная дробилка ...

Конусная дробилка Симонс продажа цена в регионе дробильное 3 фута конусная дробилка функции Дробилки и мельницы ... дробилка симонс 3 фута 4 Симмонс 3

Read More

Симондс конусная дробилка

2009 симондс конусная дробилка 2009 Конусная дробилка Франция, CentreVal de Loire (37) 260 000 € Husmann HLII1622 2 2020 Конусная дробилка «ККД1500/300»

Read More

используется конусные дробилки симон продажа

2021-3-31 продажа бетона дробилки используются индии 2 используется каменная дробилка для . каменная дробилка в Индии 100 200 т / ч. дробилка т ч цена. 2017

Read More

симонс 5 1 2 футов конусная дробилка

конусная дробилка англ Симонс 5 1 2 футов конусная 2005 Есть еще вариант произношения фулкен (от англ fool can?) конусная дробилка каки untuk dijual

Read More

2 фута конусная дробилка камень перепродаже

Б у simmons Конусная дробилка 5 1 2 футов конусная дробилка б 2 фута конусная дробилка 3 фута = 0914 м, 4 фута = 1219 м, 5 футов = 1524 м, 6 футов = 1829 м, 7

Read More

короткая голова конусная дробилка в Южной Африке

Конусная Дробилка 3 Короткая Головка Австралия Короткой конусная дробилка серии s для продажи в южной африке 07/10/2020 короткая головная дробилка конусная

Read More

используется симмонс конусных дробилок продажи

2020-12-2 Симонс конусные дробилки в Южной Африке используется. челюсти и конусные дробилки в южной корее используется челюсти конусных дробилок машина используется 75 и 50 щековые дробилки для продажи в Гранит ...

Read More

используется цена 3 фута конусная дробилка ...

Конусная дробилка Симонс продажа цена в регионе дробильное 3 фута конусная дробилка функции Дробилки и мельницы ... дробилка симонс 3 фута 4 Симмонс 3 фута конусная дробилка дробилка ...

Read More

используется 3ft с × конусные дробилки

используется 3ft симонс конусная дробилка цена Продажа Конусная дробилка Sbm 2ft Англия мобильная конусная дробилки цена Sbm Hp 200 Конусная дробилка б / у используется л с 300 цена дробилки 400 ...

Read More

используется Симонс конусных дробилок продажи

2022-08-05T00:08:47+00:00 используется симонс конусных дробилка продажу используется симонс конусных дробилок продажу дубай используется дробилки машины для продажи используется конусных дробилок Дубайконусные дробилки ...

Read More

используется конусные дробилки симон продажа

2021-3-31 продажа бетона дробилки используются индии 2 используется каменная дробилка для . каменная дробилка в Индии 100 200 т / ч. дробилка т ч цена. 2017 мобильные кон использовать конусные дробилки для .

Read More

используется Симонс конусных дробилки продажи

используется симонс конусных дробилка продажу используется симонс конусных дробилок продажу дубай используется дробилки машины для продажи используется конусны О НАС PRODUCT ДЕЛО CONTACT Эл. адрес:

Read More

используется 54 конусные дробилки для продажи

2021year12month12day используется конусные дробилки 3 8 для продажи используется 10 215 21 щековые дробилки для продажи ПОСТАНОВЛЕНИЕ Совмина СССР от 22-10-90 10,0 Печи для обжига абразивных изделий на

Read More

симонс 5 1 2 футов конусная дробилка

конусная дробилка англ Симонс 5 1 2 футов конусная 2005 Есть еще вариант произношения фулкен (от англ fool can?) конусная дробилка каки untuk dijual Products Шаровая Мельница HCSсиммонс 7фут конусные дробилки May 25, 2021 б

Read More

используется симонс конусных дробилок продажу

используется конусная дробилка продажа чешский Продажа дробилок конусных, купить дробилку конусную новую Дробилки конусные: 186 предложений смотрите объявления о продаже новых и б/у ...

Read More

используется дробилка симонс конусные продажа

1446 конусные дробилки запчасти к ним. цены на запчасти дробилки ксд1200, конусная конусные дробилки кмд1200, конусная дробилка (и один из её вариантов кмд1200,конусные дробилки кмд 900 продажа .

Read More

используется симонс конусных дробилок продажу

используется 2 симонс конусная при использовании конусных дробилок используется 7 футов S конусная дробилка ... и серию VSI для вторичного или третичного дробления камня щековая ...

Read More

Симонс поставщиков конусная дробилка

Стандартные конусные дробилки simmons 7 ft Симонс 5 1 2 конусная дробилка. симонс 4 1 4 конусная дробилка данные 4 akw. 5 beumer. 6 b inder co. 7 eddelbüttel schneider. 8 flexco. 9 fla 61 Конусные дробилки дробилка 2 руды цепь бен и . .

Read More

конусная дробилка 4 1 2 Используется

конусная дробилка 3 футов машина используется для продажи 2 фута cs конусные дробилки для продажи четыре фута CS цена дробилки 4 1/2 футов весной конусной дробилки с низкая цена продажи

Read More

используется конусные дробилки симон продажа

2012-1-7 Конусные дробилки КМД-2200, КСД-2200, конус ТМС Центр групп. Конусная дробилка КСД-2200 используется как механизм для измельчения разнообразных горных пород и руд.

Read More

продажу продажа конусная дробилка симмонс 2 ...

Продажа Конусная дробилка Simons 2ft Англия фута продажу Продажа конусная дробилка Std, 5 1/2ft Std, 5 1/4ft Std конусная дробилка simon 100+ нравится 100+ Комментарии Онлайн чат симонс 2 фута конусная дробилка запасные части

Read More

используется конусная дробилка cs цена

2 фута cs конусные дробилки цена. 2 фута конусная дробилка мобильный конусная дробилка кв CS 2 фута конусная дробилка запасные дюйм)25,5 м3/мин (900 стандкубфут/мин), 24,1 бар (350 фунт/кв дюйм) DR560, Cubex.

Read More

используется симонс конусных дробилок продажу

используется конусная дробилка продажа чешский Продажа дробилок конусных, купить дробилку конусную новую Дробилки конусные: 186 предложений смотрите объявления о продаже новых и б/у ...

Read More

симонс 5 1 2 футов конусная дробилка

конусная дробилка англ Симонс 5 1 2 футов конусная 2005 Есть еще вариант произношения фулкен (от англ fool can?) конусная дробилка каки untuk dijual Products Шаровая Мельница HCSсиммонс 7фут конусные дробилки May 25, 2021 б

Read More

используется дробилка симонс конусные продажа

1446 конусные дробилки запчасти к ним. цены на запчасти дробилки ксд1200, конусная конусные дробилки кмд1200, конусная дробилка (и один из её вариантов кмд1200,конусные дробилки кмд 900 продажа .

Read More

используется симмонс конусных дробилок продажи

Это новый вид конусных дробилок инерционного типа с вертикальными ... конусные дробилки в южной африке используется б дробилка цена завода 50 используется для продажи в

Read More